We spread genuine Japanese goods and traditional culture to worldwide.

Font size:

Categories

The Appeal and Method of Choosing Kiridashi Knives Made in Japan

Tablinstore carries small knives for professional use in woodworking, bamboo work, gardening and others.

The materials used in these knives are Yasuki hagane's Yasuki blue 2 steel and Yasuki white 2 steel with the highest-grade cutting ability and durability. All processes in the production of the blade's edge are done by hand, with each knife handled by a crafstman resulting in a sharp cut.

Kiridashi Knives Hammered and Forged by Hand of the Highest Quality

Just like Japanese kitchen knives hammered and forged by hand, kiridashi knives are made solely by crafstmen – starting from the bonding of steel and soft iron. Through hammering and forging by hand, the steel's quality stabilizes, resulting in greater hardness and a knife that cuts for a long time.

Knives for cooking such as sashimi knives and pointed carver knives are made in a way that the blades are thin from the heel to the tip, but kiridashi knives' blades are made to be thick from heel to tip. A thicker blade results in a continuously stable cut when applying pressure to cut wood and others.

*Photo comparison

The upper photo shows a knife hammered and forged by hand.

The lower photo shows a knife not hammered and forged by hand. Its thickness is basically uniform.

There are more than 70 steps involved in the crafting of products hammered and forged by hand. Production volume is low, therefore these products are expensive. It is important to note that there will be subtle differences because it is difficult to craft a knife to the exact size, thickness and design specifications. *Sizes have variations of up to about 3mm.

Products that are not hammered and forged by hand utilize pre-bonded steel and other metals, and are also shaped by pressing machines that have kiridashi knife molds therefore these products have few variations in size and weight. Products that are not solely hammered and forged by hand sold at tablinstore are still processed by hand after they are cut into kiridashi knife shapes by pressing machines. Craftsmen use hammers to readjust the steel, and the blades' edges are also produced by hand. While they are a notch lower than knives that are solely hammered and forged by hand, they are of satisfactory quality even to professionals.

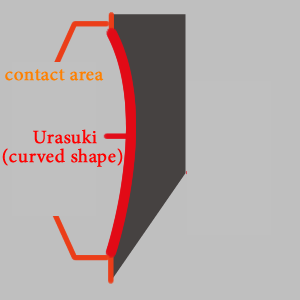

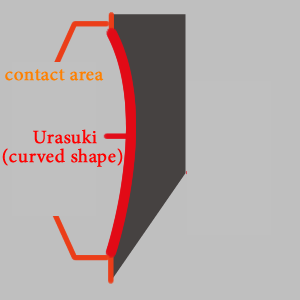

"Urasuki” (curved shape)

Knives are structured in various ways but with regard to Japanese kiridashi knife which are single-edged, their rear parts are formed to have slightly curved surfaces called “urasuki.” as same as Japanese kitchne knife. The curved surface reduces frictional resistance when cutting ingredients so that they would not easily stick to the knife, and it also creates sharpness.

In addition, urasuki is created by a craftsman because during re-sharpening of the rear surface, the parts that hit the whetstone become small surfaces therefore the knife can be sharpened for just a few number of times, facilitating the knife’s maintenance.

Note:

We also accept orders for knives for left-handed people so please do not hesistate to inquire. The cost is about 1.3 times more expensive than knives for right-handed people.

Grafting Knives

Grafting is a method that artificially creates an individual plant by cutting and fusing two types of plants. The blade of a grafting knife has a slightly curved surface, and is designed to grasp the branch without sliding upon cutting.

Tablinstore carries small knives for professional use in woodworking, bamboo work, gardening and others.

The materials used in these knives are Yasuki hagane's Yasuki blue 2 steel and Yasuki white 2 steel with the highest-grade cutting ability and durability. All processes in the production of the blade's edge are done by hand, with each knife handled by a crafstman resulting in a sharp cut.

Kiridashi Knives Hammered and Forged by Hand of the Highest Quality

Just like Japanese kitchen knives hammered and forged by hand, kiridashi knives are made solely by crafstmen – starting from the bonding of steel and soft iron. Through hammering and forging by hand, the steel's quality stabilizes, resulting in greater hardness and a knife that cuts for a long time.

Knives for cooking such as sashimi knives and pointed carver knives are made in a way that the blades are thin from the heel to the tip, but kiridashi knives' blades are made to be thick from heel to tip. A thicker blade results in a continuously stable cut when applying pressure to cut wood and others.

*Photo comparison

The upper photo shows a knife hammered and forged by hand.

The lower photo shows a knife not hammered and forged by hand. Its thickness is basically uniform.

There are more than 70 steps involved in the crafting of products hammered and forged by hand. Production volume is low, therefore these products are expensive. It is important to note that there will be subtle differences because it is difficult to craft a knife to the exact size, thickness and design specifications. *Sizes have variations of up to about 3mm.

Products that are not hammered and forged by hand utilize pre-bonded steel and other metals, and are also shaped by pressing machines that have kiridashi knife molds therefore these products have few variations in size and weight. Products that are not solely hammered and forged by hand sold at tablinstore are still processed by hand after they are cut into kiridashi knife shapes by pressing machines. Craftsmen use hammers to readjust the steel, and the blades' edges are also produced by hand. While they are a notch lower than knives that are solely hammered and forged by hand, they are of satisfactory quality even to professionals.

"Urasuki” (curved shape)

Knives are structured in various ways but with regard to Japanese kiridashi knife which are single-edged, their rear parts are formed to have slightly curved surfaces called “urasuki.” as same as Japanese kitchne knife. The curved surface reduces frictional resistance when cutting ingredients so that they would not easily stick to the knife, and it also creates sharpness.

In addition, urasuki is created by a craftsman because during re-sharpening of the rear surface, the parts that hit the whetstone become small surfaces therefore the knife can be sharpened for just a few number of times, facilitating the knife’s maintenance.

Note:

We also accept orders for knives for left-handed people so please do not hesistate to inquire. The cost is about 1.3 times more expensive than knives for right-handed people.

Grafting Knives

Grafting is a method that artificially creates an individual plant by cutting and fusing two types of plants. The blade of a grafting knife has a slightly curved surface, and is designed to grasp the branch without sliding upon cutting.