Categories

About Tsunesaburo

Mr.Tsuenzaburo Uozumi, a first-generation plane blade maker studied under Mr. Fukuzaburo Kanna since he was a child and has mastered the secrets of process for making plane blade for 28years. He established the Tsunesaburo Plane Works Co., Ltd. in 1947. A third-generation of the Tsunesaburo family, Mr. Toru Uozumi who currently takes over a business crafts various type of plane according to the purpose of use utilizing both the traditional method and modern equipment. It provides excellent sharpness, high durability and usable from hard materials to softwood and laminated wood. The Tsunesaburo bland built a reputation all over the world especially woodworkers and craftsmen who make musical instruments.

Stable high quality

The plane is made from high class steel, mainly the finest blue steel, for core blade material and soft iron carbon steel for base blade material. The processes are all done by hand(called Koshiki tanzo). Controlling hardening and tempering, the key to make stable quality plane blade, is operated with not only depending on intuition of experienced craftmen, but using several thermometers.

*Only high-speed steel(SKH51) is done by press working.

Body stand is made from Japanese quercus myrsinifolla which is completely dried over 3 years. Hardly warped, providing strength and resistant to aged.

Special Techniques of Tsunasaburo

The easy maintenance plane blade: unnecessary “ura dashi” kanna

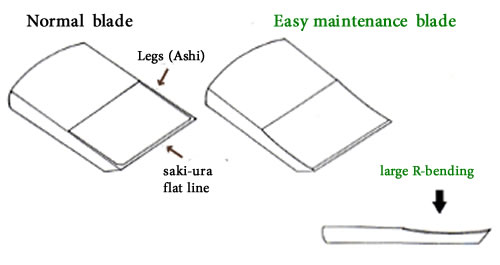

Regular plane has legs called “ashi” on both sides.(left below: necessary “ura dashi” kanna)

On the other hand, this easy maintenance plane blade doesn’t has legs but being processed as a large R-bending from the blade steel end point(Kaisaki) to the blade edge. Therefore, it’s only needed to whet back side of the blade even when the end of the blade is abraded.

FYI:How to “ura dashi kanna”

https://www.youtube.com/watch?v=_wSuN68Log0

Wrought iron steel (Rentetsu) is whet well

The refined steel imported into Japan more than 130 years ago from UK.

Old aged wrought iron steel is softer than present iron. So it's the best for base plane material.